CNC gear hobbing machine is applicable to the production and processing of cylindrical gears and worm gears in batches, small batches and single pieces, and the drum gears with certain parameters can also be used for continuous indexing and hobbing of 6 teeth and short spline shafts with a length of less than 300 and more than 6 teeth. The sprocket hob can be used to hobbe the sprocket. The cylindrical gear can be processed by the method of up-milling and up-milling hobbing, and the full tooth width can be processed by the method of axial feed (vertical feed). NC hobbing machine hobbing common worm gear is processed by radial feed method. The adjustment and processing method of the CNC hobbing machine when machining spline shaft and sprocket are the same as when machining cylindrical spur gear.

Working principle of CNC gear hobbing machine: when the pump is started, the driving wheel drives the driven gear, the driven gear rotates in the opposite direction, and there is good meshing between the gear and the gear. The teeth of the two gears scrape away some of the oil at the inlet, thus forming a low pressure suction liquid into the pump body. The liquid is divided into two channels, which is pushed forward by the gear in the gap between the gear and the pump housing, and is pressed to the oil outlet to form a high pressure and discharge. The main equipment of the blown-air recovery boiler include: combustion furnace, CNC gear hobbing machine, steam superheater, boiler body, second air preheater, soft water heater, air preheater, induced draft fan and forced draft fan.

The maintenance of each part of the CNC gear hobbing machine is very important. It can ensure that the machine tool can process products in good condition. Let's understand the maintenance of each part of the CNC gear hobbing machine:

1、 Column guide rail:

1. The bearing back cap is not loose;

2. The drive screw rod and polished rod shall be clean without oil and abrasion;

3. All sliding guide surfaces shall be clean and free of oil and abrasions;

4. The balancing device is in good condition

2、 Tool holder part:

1. The milling cutter is firmly clamped;

2. The front and rear bearing seats of the milling cutter bar are fastened and reliable;

3. The rotating fastening screw of the tool holder is not loose;

4. The milling cutter bar and taper hole shall be clean and free of grinding marks and bruises

3、 Change gear box part:

1. The gear is clean and has oil, and the meshing clearance is appropriate

2. The change gears of all parts shall be fixed reliably without jamming;

4、 Gearbox and control part:

1. The operating handle of each part is flexible, and the positioning is accurate and reliable;

2. Each hydraulic valve is sensitive and easy to use, and its position is accurate;

3. Transmission sound in gearbox is normal;

4. Hydraulic unloading works well

5、 Lubrication part:

1. The oil level in the tank reaches the oil mark line, and the oil mark wakes up;

2. The oil pressure meets the specified range;

3. The oil circuit of the oil pump is unblocked and works normally without oil leakage;

4. The oil cup and oil hole are clean and have oil;

5. The lubricating tools are complete and clean

6、 Workbench part:

1. Worm gear pair shall be well lubricated without abrasion;

2. The workbench rotates flexibly without shaking;

3. The worktable shall be free of scars

7、 Safety device of CNC gear hobbing machine:

1. Each brake is sensitive and easy to use;

2. Each limit switch acts sensitively and the stop is fastened and reliable;

3. All protective covers are complete and fixed reliably;

4. All instruments and signal devices are complete, sensitive and accurate

8、 CNC gear hobbing machine accessories:

1. Accessories are complete and clean;

2. Place reasonably and neatly

9、 Electrical part:

1. The line is fixed neatly and the insulation is reliable;

2. All switches are sensitive and easy to use;

3. The motor is clean and operates normally

10、 Cooling part:

1. The oil tank is clean and free of sundries;

2. The pipeline is smooth without oil leakage;

3. The cooling pump and pipeline are fastened firmly and work normally.

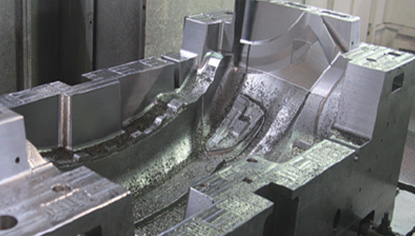

Gantry machining center

Gantry machining center Linear motor machining center

Linear motor machining center Horizontal machining center

Horizontal machining center High speed gantry machining center

High speed gantry machining center hobbing machine

hobbing machine Vertical machining center

Vertical machining center High precision engraving and milling machine

High precision engraving and milling machine FA-UM630 Crane Cradle Five Axis Ultrasonic Machining Center

FA-UM630 Crane Cradle Five Axis Ultrasonic Machining Center FA-UM800 Crane Cradle Five Axis Ultrasonic Machining Center

FA-UM800 Crane Cradle Five Axis Ultrasonic Machining Center