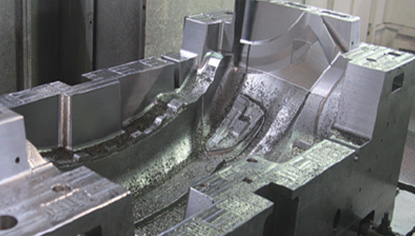

Ningbo Dekai CNC reminds you to pay attention to the safe use of CNC high-speed machines! The CNC high-speed machine adopts horizontal and vertical layout, adopts simultaneous drive at both ends, and has locking function during processing. The machine has high strength and rigidity, and can realize high-speed milling of inner and outer straight and helical gear rings.

Precautions for safe use of CNC high-speed machine:

1. Before starting the machine, determine the workpiece processing requirements. If it is drilling, turn the switch to the drilling indication. If it is tapping, turn the switch to the tapping indication. The workpiece must be firmly clamped on the fixture; Fill/grease according to the lubrication regulations, and insist on whether the control mechanism is flexible.

2. Before working, carefully check the workbench, guide rail and main sliding surfaces. If there are obstacles, tools, scrap iron, impurities, etc., they must be cleaned, wiped and oiled.

3. Do not wear gloves during work.

4. When using the extension bit to drill deep holes, the cuttings must be removed frequently; When the plane needs to be milled after drilling, the hand wheel must be pulled by hand for inching (milling), and no motorized feeding is allowed.

5. When removing tools such as drill bit, drill sleeve, drill chuck, etc., it is necessary to use standard wedge iron to punch down or use drill clamp wrench to loosen, and it is not allowed to use other tools to knock along.

6. When machining parts, all parts shall be locked, and the machine shall not be stopped until the tap is out of the workpiece;

7. The operator should stop the machine when leaving the machine tool, changing the speed, changing the tap, cleaning the machine tool, etc;

8 During the work, the workpiece must be clamped on the workbench or vice, and it is not allowed to drill or tap the workpiece by hand under any circumstances.

9. Do not use too much force when drilling and when the hole is about to be drilled through; When drilling through holes, the bottom of the workpiece must be padded to avoid damaging the workbench or vice; Use the power feed to drill through the hole. When it is close to drilling through, the power feed must be stopped and replaced by manual feed.

10. If the machine tool breaks down or is abnormal, it should be stopped immediately for troubleshooting.

11. After the work is completed, clean the tools, parts and work site, wipe out all parts of the equipment (ensure that the equipment appearance is free of oil stain, dust and sundries on the work table), and lubricate the sliding surfaces for protection.

Gantry machining center

Gantry machining center Linear motor machining center

Linear motor machining center Horizontal machining center

Horizontal machining center High speed gantry machining center

High speed gantry machining center hobbing machine

hobbing machine Vertical machining center

Vertical machining center High precision engraving and milling machine

High precision engraving and milling machine FA-UM630 Crane Cradle Five Axis Ultrasonic Machining Center

FA-UM630 Crane Cradle Five Axis Ultrasonic Machining Center FA-UM800 Crane Cradle Five Axis Ultrasonic Machining Center

FA-UM800 Crane Cradle Five Axis Ultrasonic Machining Center